Factory information

About 40 years experience and technologies

We manufacture products one by one carefully with about 40 years experience and technologies following the strict standards of quality control in the clean factory which has a good manufacturing environment.

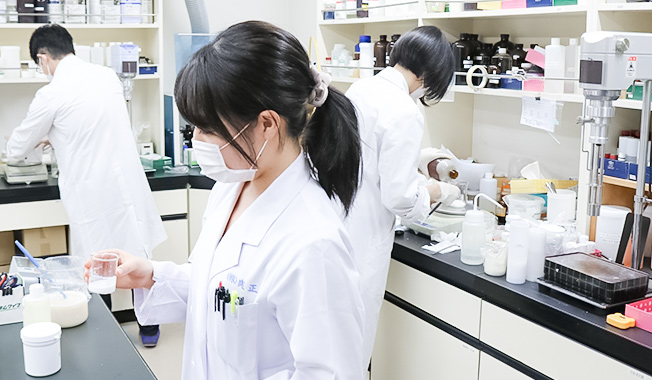

R & D

We develop and submit products which satisfy your requests adopting domestic and foreign new materials based on the development prescriptions gained for about 40 years.

We guarantee those products to be safe and stable using various evaluation and analysis equipment so that you can sell them free from anxiety.

- Cleanliness measurement device

- High-speed centrifuge

- Particle size distribution measurement device(SALT7500nano)

- Ion meter

- B-type viscometer

- Stereoscopic microscope

- Cell culture device etc. (Phase contrast microscope, Microplate reader, Slow centrifuge, Ultra-low temperature freezers, CO2 incubators)

- Supercritical carbon dioxide extraction apparatus

- Vacuum emulsifying machine

- High-pressure emulsifier

- Planetary mixer

- Homo mixer

- Homo disperser

Weighing

We strictly control accuracy of weighing materials procured using the computer-operated weighing system.

Mixing/Manufacturing

We respond to customer's needs from small lot production to large lot one with our cosmetics manufacture (preparation) equipment. We have manufacturing floors which are hygienic and safe, enabling us to relieve and satisfy customers.

The products made with our professionals' techniques that are compared with craftsmanship on the floors which are hygienic and safe are well-finished ones only we can produce.

- Ultrapure water manufacturing system

- 3-chamber electrolysis water generator

- Vacuum emulsifying machine

- High-pressure emulsifier

- Planetary-type multi-purpose corresponding vertical mixer

- Other types of mixers

- Weighing system

Filling/Packing

Cosmetics finished in the preparation process are filled after undergoing quality inspection. Making the filling floor complete so that we can respond to various kinds of cosmetics in small quantities, we handle one by one with the greatest care.

- Liquid quantitative automatic filling machine

- High viscosity filling machine

- Hot pressure filling machine

- Ultrasonic sealing type automatic tube filling machine

- Automatic inline capping machine

- Small bottle capping machine

- Automatic pillow shrink packaging machine

- Various packaging related equipment

- Dispenser

- Peristaltic Dispenser

- Checkweigher

Quality Assurance

We thoroughly practice quality management from procurement of raw materials to manufacture so that we can provide customers with products which satisfy them.

We raise our belief "Customers' prosperity leads to our growth." high as our Quality Policy.

- Colorimeter

- Liquid Chromatography

- Gas chromatography

- Various constant temperature bath

- Clean bench

- Microscope

- Ion meter

- B-type viscometer

- Autoclave

- Electronic balance

Quality Policy

We put the highest priority on providing safe and reassuring products.

We realize customer expectations with our leading technology, superb quality, and highly efficient management.

We sincerely take customer expectations and make the best of them to further improve the company.

We establish fare and reliable relationships with customers, suppliers, and employees and comply with applicable laws and regulations, acting as a responsible citizen.

We repeatedly learn, follow, and utilize the quality management system, updating the system according to changes to get ready for tomorrow.

We regard our employees’ initiative as the motive of improvement, and we create a working environment where it is accepted.